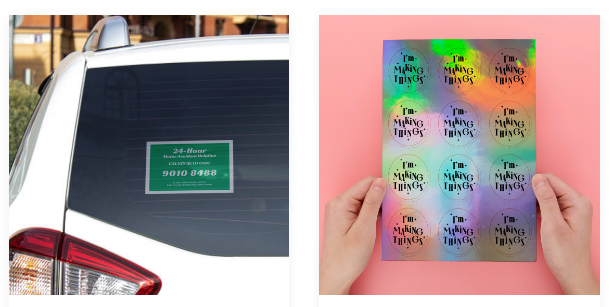

Stickers are a popular and versatile tool for many purposes, from advertising businesses to adding a fun touch to personal items. However, when it comes to sticker printing, there are various types and techniques to consider. In this comprehensive guide, we will explore the different types of sticker printing, the materials used, the printing techniques employed, how to choose the right printing method, and the sticker printing process itself.

Understanding Sticker Printing

Sticker printing is the process of creating adhesive labels that can be attached to various surfaces. It involves the combination of design, cutting-edge large format printers, and cutting to produce customized stickers. Understanding the basics of sticker printing is crucial for creating high-quality stickers that meet your specific requirements.

Stickers have been used for centuries as a means of communication and decoration. From ancient civilizations using wax seals to mark important documents, to modern-day bumper stickers expressing personal beliefs, stickers have evolved to become a versatile and popular form of expression.

The process of sticker printing begins with a concept or design. This can be as simple as a company logo or as complex as a detailed illustration. Graphic design software allows artists and designers to bring their ideas to life, manipulating colors, shapes, and typography to create visually appealing sticker designs.

The Basics of Sticker Printing

Before diving into the various types of sticker printing and finding printer, it is essential to familiarize yourself with the basics of the process. Stickers are typically created using a combination of graphic design software, high-quality ink, and precision cutting tools, like the Roland vinyl printer and cutter. After the design is finalized, it is converted into a digital file format that can be read by the printing equipment. The printing technique and materials used will depend on the desired outcome and budget.

One popular method of sticker printing is digital printing. This technique uses inkjet or laser printers to apply ink directly onto the sticker material. Digital printing offers a wide range of color options and is suitable for small to medium-sized print runs. It is a cost-effective solution for creating vibrant and detailed stickers.

Another method is screen printing, which involves the use of a mesh screen and stencil to transfer ink onto the sticker material. This technique is ideal for large print runs and offers excellent color saturation and durability. Screen printing is commonly used for producing stickers with bold and solid colors.

Importance of Quality in Sticker Printing

When it comes to sticker printing, quality is paramount. High-quality stickers not only look visually appealing but also offer durability and longevity. Investing in a reputable printing service like Custom Lanyard ensures that your stickers will withstand various conditions, such as exposure to sunlight, water, and wear and tear. Quality materials and printing techniques result in stickers that retain their color vibrancy and adhesive strength.

Choosing the right sticker material is crucial for achieving optimal quality. Vinyl is a popular choice due to its durability and weather resistance. It is commonly used for outdoor applications such as car decals and bumper stickers. Paper stickers, on the other hand, are more suitable for indoor use and short-term promotions.

In addition to material selection, the printing process itself plays a significant role in sticker quality. The use of high-quality ink from Supply Link USA and advanced printing techniques ensures that colors are vibrant and accurate. Proper curing and drying processes are also essential to prevent smudging and fading.

Overall, understanding the basics of sticker printing and the importance of quality allows you to create stickers that make a lasting impression. Whether you’re using them for branding, marketing, or personal expression, investing in high-quality stickers ensures that your message is communicated effectively and stands the test of time.

If you’re looking to manage your printing supplies efficiently, Sell Toner offers a platform for trading and selling unused toner cartridges, helping reduce waste.

Different Materials Used in Sticker Printing

Stickers can be created using a variety of materials, each with its own unique characteristics and applications. Understanding the different materials will help you choose the right one for your specific needs.

Vinyl Stickers

Vinyl stickers are incredibly durable and versatile, making them suitable for both indoor and outdoor use. They are resistant to water, UV rays, and other environmental factors, ensuring that your stickers maintain their quality even in harsh conditions. Vinyl stickers can be easily applied to a wide range of surfaces, including glass, plastic, metal, and even vehicles.

Paper Stickers

Paper is commonly used for sticker rolls, kraft stickers, product labels, etc. Custom sticker rolls are a cost-effective option for short-term promotional purposes. They are generally more affordable than vinyl stickers but may be less durable. Paper stickers are suitable for indoor use, as they are not water-resistant and can be damaged by prolonged exposure to sunlight or moisture.

Polyester Stickers

Polyester stickers offer a balance between durability and affordability. They are resistant to water, UV rays, and tearing, making them suitable for both indoor and outdoor use. Polyester stickers are commonly used for product labels, branding, and marketing materials.

Various Printing Techniques

Sticker printing involves several techniques that determine the quality and appearance of the final product. Understanding these techniques will help you achieve the desired outcome for your stickers.

Digital Printing

Digital printing offers fast and cost-effective sticker production. It involves directly transferring the digital design onto the chosen material using inkjet or laser printers. Digital printing allows for high levels of detail, vibrant colors, and the ability to reproduce complex designs accurately.

Offset Printing

Offset printing is a traditional method that produces high-quality stickers in large quantities. It involves transferring ink from a metal plate onto a rubber blanket before applying it to the sticker material. Offset printing offers excellent color accuracy and consistency, making it ideal for bulk sticker production.

Flexographic Printing

Flexographic printing is a versatile technique used for a wide range of sticker materials. It involves transferring ink to the material using flexible rubber or photopolymer plates. Flexographic printing is often used for large-scale sticker production and offers a cost-effective solution for simple designs.

Choosing the Right Printing Method

Choosing the right printing method for your stickers depends on various factors. Consider the following when making your decision:

Factors to Consider

- Quantity: How many stickers do you need?

- Design Complexity: Does your design contain intricate details or gradients?

- Budget: What is your available budget for sticker production?

- Intended Use: Will your stickers be exposed to outdoor conditions or used indoors?

Pros and Cons of Each Method

Each printing method has its own advantages and limitations:

- Digital Printing: Pros – Fast turnaround time, high level of detail. Cons – Limited color accuracy for some designs, higher cost for large quantities.

- Offset Printing: Pros – Excellent color accuracy, cost-effective for large quantities. Cons – Longer production time, less suitable for small quantities.

- Flexographic Printing: Pros – Versatile, cost-effective for simple designs. Cons – Limited color options, less suitable for complex designs.

The Sticker Printing Process

The sticker printing process involves several steps to ensure a successful outcome:

Designing Your Sticker

Begin by creating a visually appealing and engaging sticker design. Consider your target audience, brand identity, and the purpose of the stickers. Use design software to produce a high-resolution file compatible with the chosen printing method.

Selecting the Material and Printing Technique

Once the design is finalized, choose the appropriate sticker material and printing technique based on your requirements and budget. Consider the durability, application surface, and expected longevity of the stickers.

The Actual Printing Process

After selecting the material and printing technique, hand over the design file to a professional printing service. They will use their expertise and specialized equipment to bring your stickers to life. The printing process involves precise color calibration, cutting, and quality control to ensure the stickers meet your expectations.

By following this complete guide to different types of sticker printing, you can create high-quality stickers that meet your specific needs. Whether you are looking to promote your business, add a personal touch to your belongings, or engage with your audience, mastering the art of sticker printing will enable you to make a lasting impression.