When you’re on the hunt for a plastic fabrication service, it can feel a bit like trying to find a needle in a haystack.

With so many options out there, how do you ensure you’re picking the right one for your project?

Whether you’re a business owner in need of bespoke components or a creative individual looking to bring your vision to life, selecting the right service is crucial.

Here are five essential considerations to guide you through the process, ensuring you make an informed decision.

Understand Your Project Requirements

First things first, you need to have a clear understanding of your project’s requirements. What type of plastic do you need? Are there specific properties it must have, such as being food-safe or UV resistant?

The complexity of your design also plays a significant role. Some services specialise in simple shapes, while others thrive on intricate designs and detailed work.

Knowing your project’s specifics will help you narrow down potential services that are best equipped to meet your needs.

Assess Their Expertise and Experience

Not all plastic fabrication services are created equal. It’s essential to delve into the expertise and experience of the companies you’re considering. How long have they been in the business?

Do they have a portfolio of projects similar to yours? Experience in your specific industry can be a huge advantage, as it means they’re likely familiar with the common challenges and requirements.

Don’t hesitate to ask for case studies or examples of their previous work.

Consider the Quality of Materials

The quality of materials used in your project will directly impact its durability, appearance, and functionality. Ensure the service you choose does not cut corners when it comes to materials.

For instance, if you’re looking for a lightweight, versatile plastic option, foamex at Simply Plastics is known for its quality and durability.

It’s crucial to select a service that sources high-quality materials and can provide the necessary documentation to back up their claims.

Evaluate Their Technology and Capabilities

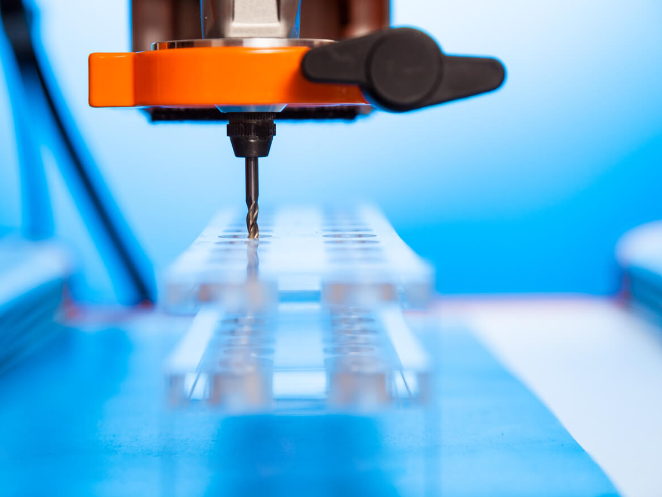

The technology and machinery used by a plastic fabrication service can significantly affect the quality, precision, and efficiency of the final product. Do they utilise the latest technology?

Are they capable of CNC routing, laser cutting, or whatever specific technique your project requires?

A service that invests in the latest technology is likely committed to providing the best possible outcomes for their clients.

Analyse Their Customer Service and Communication

Finally, never underestimate the importance of good customer service and clear communication. The process of bringing a project to life can be complex, and having a responsive, helpful team can make all the difference.

Are they quick to respond to enquiries? Do they provide clear, understandable answers to your questions? A company that values its customers will ensure the process is as smooth and stress-free as possible.

Decision time: ensuring your Plastic Fabrication choice is spot on

Selecting the right plastic fabrication service is a pivotal decision that can influence the success of your project.

By considering your project’s specific requirements, assessing the expertise and experience of the service, ensuring the quality of materials, evaluating their technology and capabilities, and analysing their customer service and communication, you’re setting yourself up for a successful partnership.

Remember, the goal is to find a service that not only meets your needs but also exceeds your expectations, ensuring your project is in capable hands from start to finish.