There is a product which is very vital in the present methods of mining, and it is magnetic disc separators or MDS for short. Whether you are starting a new venture in the field or need more information on how these machines work and how they can be used in mining, this article will be helpful. Being one of the important and commonly used equipment in mineral processing plants, Magnetic disc separators play an important role of achieving high rate of recovery and thus improving the productivity of mineral processing plants.

Magnetic Disc Separators

Magnetic disc separators are a specific kind of equipment that is used for separation of materials with different magnetic characteristics. These separators employ intense magnetic fields to pull-off magnetic material from non-magnetic material. The principal working components of these separators are a number of rotating magnetic discs each with distinct magnetic field strength. This multi-disc approach enables operators to mine numerous materials including iron, tungsten and rare earth in the same process.

These machines are particularly flexible in application since they can be employed on various materials of varying size and magnetic properties. They are usually employed in closed circuit with other subsequent mineral processing equipment, like vibrating screens to properly classify the feed material by size and to exclude unwanted elements. Such a separator as a magnetic disc separator used in mining leads to effective sorting of resources and reduces wastage. The portable use of these separators makes them ideal both in the large scale industries and small specially contracted industries making them valuable in modern flotation of minerals.

How Magnetic Disc Separators Work

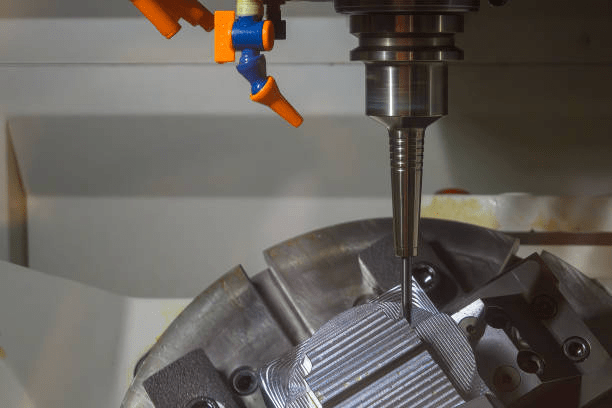

Magnetic disc separators are mainly for operation depending on the magnetic field where materials with magnetic properties are those attracted to and separated by different magnetic fields. The ore is fed onto a conveyor belt which is located immediately below the magnetic discs in the structure of the spinning wheel. These discs are located optimally thereby establishing regions of almost high magnetic density so that even the least magnetic materials are trapped.

The material goes through the separator at which stage the magnetic particles are attracted to the discs and grouped into specific dump zones. Iron-bearing materials are then ejected out of the conveyor while non-magnetic materials move along the conveyor for other processing or disposal. The separator’s effectiveness is charged on the fact that it has variable magnetic field strengths for target mineral and variable speeds of discs.

When combined with a magnetic disc separator, the vibrating screen filters only the right size of particles thereby improving the performance of the machine. This eliminates transfer bottlenecks and enhances flow, it is a strong solution for the mineral processing industry. Magnetic disc separator captures this accuracy and effectiveness without compromise for amount so it becomes a vital tool for mining industries.

Use of The Magnetic Disc Separator in Mining

The applications of the magnetic disc separators are diverse, and they find their use in almost all categories within the mining industry to recover valued minerals as well as enhancing product quality. One of their main uses is in the process of obtaining metals with imbalance in the relation between their demand and supply, crucial for developing modern technologies, including wind turbines, electric cars, and smartphones. These separators are also important in the course of processing such minerals as quartz, feldspar and kaolin whose purity requires elimination of iron materials.

Apart from non-metallic minerals, magnetic disc separators are applied widely when sorting metallic ores. For example, they help in the processing of ilmenite which, garnet and wolframite since these minerals in order to be separated must go through different magnetic processes because of the difference in their magnetic characteristics. Another area of its application is in the preparation of coal in separation and elimination of pyrite and other impurities that affect combustion quality of the fuel.

This is especially owing to the ability of magnetic disc separators to handle as well as separate different materials without the necessity of the use of chemicals. Its compatibility with other mineral processing equipment makes it easy for an efficient through production line without shedding. Through such broad applications it is clear that they play a significant part in today’s mining as well as contribute to change and sustainability in the industry.

Advantages of Magnetic Disc Separators

Magnetic disc separators I consider as the most valuable equipment used in mineral processing for several reasons. One of their key advantages is their versatility of handling stock with variable magnetic characteristics. Such fluid this multi-disc setting means separation of multiple minerals at once and thus increases efficiency in the process and decreases costs. They are also easily modifiable; fluctuations in the strength of the magnetic fields and the discs’ RPMs may also vary depending on mining necessities.

Its small size makes it possible to incorporate them with other systems common in the vibrating and other processing equipment such as the crusher and other related equipment. Magnetic disc separators also help to minimize the application of chemicals, which makes such machines somewhat more environmentally-friendly. In addition, these machines are constructed for longevity and present little need for maintenance; this means that the operational costs are as low as they can be and there will be little to no interruptions.

Purchasing better-quality magnetic disc separators would increase productivity in terms of efficiency and effectiveness since it reduces by percentages the proportion of unwanted materials in formulating high-quality final product. Due to their applicability to various types of materials and industries, these devices remain indispensable for current mineral processing; in the long run, their advantages outweigh the cost of acquisition.

Conclusion

Magnetic disc separators are a very important aspect in the modern mining industry because of the efficiency it has in terms of the separation of the magnetic and non magnetic material. Being key components of mineral processing, they increase recovery, improve the quality of the end product and optimize processes. Due to its efficient accommodation of other related systems, like vibrating screens and conveyors, there is the achievement of the best performing system. Magnetic disc separators are suitable no matter whether it is rare earth elements that are being processed or industrial minerals or metallic ores. It enables operators to make right decisions in order to increase productivity while keeping the environmental impacts of these structures almost negligible. This may be the ideal opportunity then for newcomers to the mining business or companies seeking to enhance their performance to opt for the magnetic disc separators as the means to get the business ahead of the competition as far as efficiency is concerned.